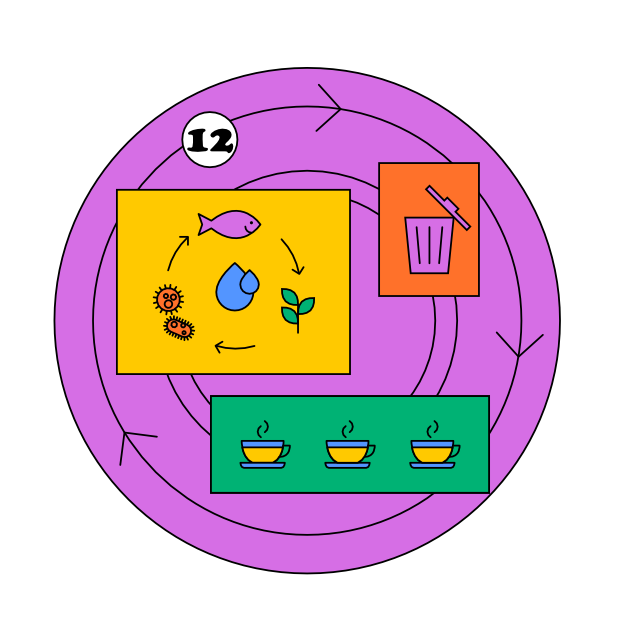

SDG 12Responsible consumption and production

Is it possible to keep consumption and production at bay at all?

Overview

It is, without exaggeration, very difficult not to waste in today’s world. The true cost that we all and the planet are paying for our goods is invisible. The price tag in crowns, euros or dollars is absolutely misleading. In some cases, the choice is easy: flying to Australia will always have a greater impact on the planet than going to a nearby village. In others, however, the environmental and other costs of goods are difficult to track for customers.

At the same time, it is clear that our demands on Earth are increasing. In 2050, the planet’s population will be nearing 10 billion. If we were all to live in the same way as the developed world lives today, we would need three more Earths to maintain our standards. The twelfth SDG is, therefore, clear – to save food, raw materials, and energy. The question is – how?

Solution and Key Innovations

To illustrate it, we can simply draw a circle. The result is the circular economy, in which no resource goes to waste and is returned back into circulation. For example, electronic waste contains metals ranging from aluminium to copper and gold which have no expiration date. Food that is thrown away contains organic matter that can be used as fertiliser or food for less picky organisms. Even better, we can ask if this all had to end up in waste in the first place.

Currently, the global economy is about 8.6% circular – the potential is huge. If its volume could be doubled in this decade, global greenhouse gas emissions could be reduced by more than a third and humanity’s total material footprint reduced by 28% compared to current levels. That’s the estimate in the Circularity Gap Reporting Initiative’s regular report, which is always published on the occasion of the well-known Davos meeting.

There are a number of opportunities that help make economics more circular, with some of them vital, such as the European HIGREEW project which aims to develop a new generation of batteries for storing electricity in large volumes. These are the so-called flow batteries with large tanks of liquid electrolyte. Similar batteries already exist, but the new European ones are cheap and non-toxic (with water-soluble electrolyte) – and have very long life.

There are also more modest solutions. Zemanka, the Czech organic bakery produces crackers from Pilsner Urquell beer grounds and biscuits from coffee grounds. It is the first Czech company to release a sustainability report and a strategy for the next five years in which the bakery’s sustainability activities are summed up, and maps the use of resources from energy and water consumption to the origin of raw materials and recycling. The company’s goal is to nothing less than to become Europe’s first fully sustainable bakery and to be a role model for others.

Organic waste is used in a different way at the Agricultural Cooperative of Breeders and Growers Litomyšl. It is one of the first installations for the production of biomethane and its injection into the gas distribution network. The processing of cow manure and agricultural crops produces gas of natural gas quality, which will then flow into the gas pipelines. The whole process is more efficient than conventional biogas production.

The Czech Future Farming company on the other hand, strives to ensure that consumers have access to healthy local food. This is possible thanks to aquaponic production, i.e., growing food in special facilities that use 95% less water than conventional approaches. Sophisticated hydroponic farms, in which the entire growing cycle is managed to the smallest detail, also allow for the perfect use of other inputs such as energy or fertilisers. The company has already built two aquaponic farms, one of which is focused on science and research in collaboration with the Academy of Sciences and several Czech universities.

In recent years, there has been increasing evidence that small fragments of plastic – microplastics – are all around us. Removing them from the environment is not easy with the methods available today, so new solutions are being sought. One example is the European RECOVER project. Researchers are looking for natural solutions to the problem. The aim is to find the right combination of tiny organisms – from bacteria to insects to earthworms – to deal with microplastics. These organisms would turn them – ideally in just one step – from waste into fertiliser or other usable biological material.

Key Questions

- Can we reduce food waste?

- Will we be using recycled materials more?

- How can we reduce current waste production?

Key Words

Sustainability, raw materials, energy, circular economy, waste, production,

Interesting Resources

- Tyres could be used as raw material for concrete production

- New enzyme helps turn plastic waste into valuable raw material

- Wind turbine blades can be easily recycled into basic raw materials using a new method

- Waste is finding a place in wearable electronics

- More efficient methods to turn carbon dioxide into fuel